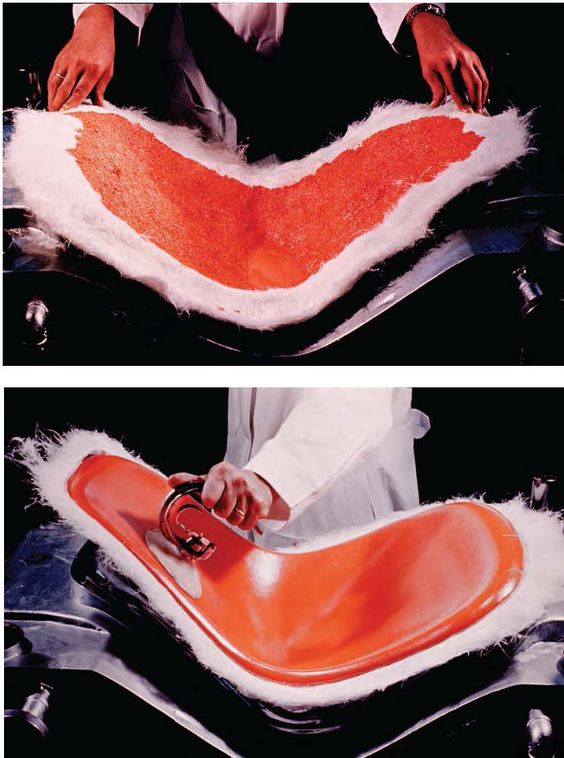

Fibreglass is used in many industries for moulding because it is inexpensive. However, it was discovered that it becomes stronger when fibreglass is added to the resin. Fibreglass also has a chemical, impact, corrosion resistance, and a high strength-to-weight ratio.

Industrial Uses of Fibreglass Moulding

1. Boat Industry

The majority of a boat’s components are made of fibreglass. Fibreglass was first used to shape a boat in 1942, and boat manufacturers have since relied on it because wood, aluminum, and steel are more difficult to use and more expensive. Fibreglass is also used to make the boat’s deck, table, and chairs.

2. Furnishings for the Home

In the 1970s, fibreglass furniture gained popularity for outdoor items like patio sets, pool loungers, and garden chairs due to its durability, lightweight construction, and weather resistance. Technological advancements enabled more intricate designs and better finishes, enhancing its versatility and appeal. This innovation transformed outdoor living spaces, resulting in modern and practical furniture options for various settings.

3. Attractions in Amusement Parks

The slides, troughs, and funnels in amusement parks and water parks are all made of fibreglass.

4. Electronics

All electronic circuit boards are made of fibreglass. They are used in the manufacture of laptops, computers, and mobile phones.

5. The Automobile lndustry

The first car made of fibreglass was introduced in 1953. Fibreglass is used in automobile design because it is flexible and allows for easy customisation and replacement of parts. It is also used because it is inexpensive, long-lasting, and efficient.

6. Aerospace and Aircraft

The sturdiness, durability, and lightweight properties of fibreglass meet the requirements for materials used in aircraft construction. S-glass fibreglass is primarily used in the aerospace industry. Its ability to withstand stress and higher temperatures are two other properties that make it suitable for use. They also have high mechanical strength and are non-conducting.